Description

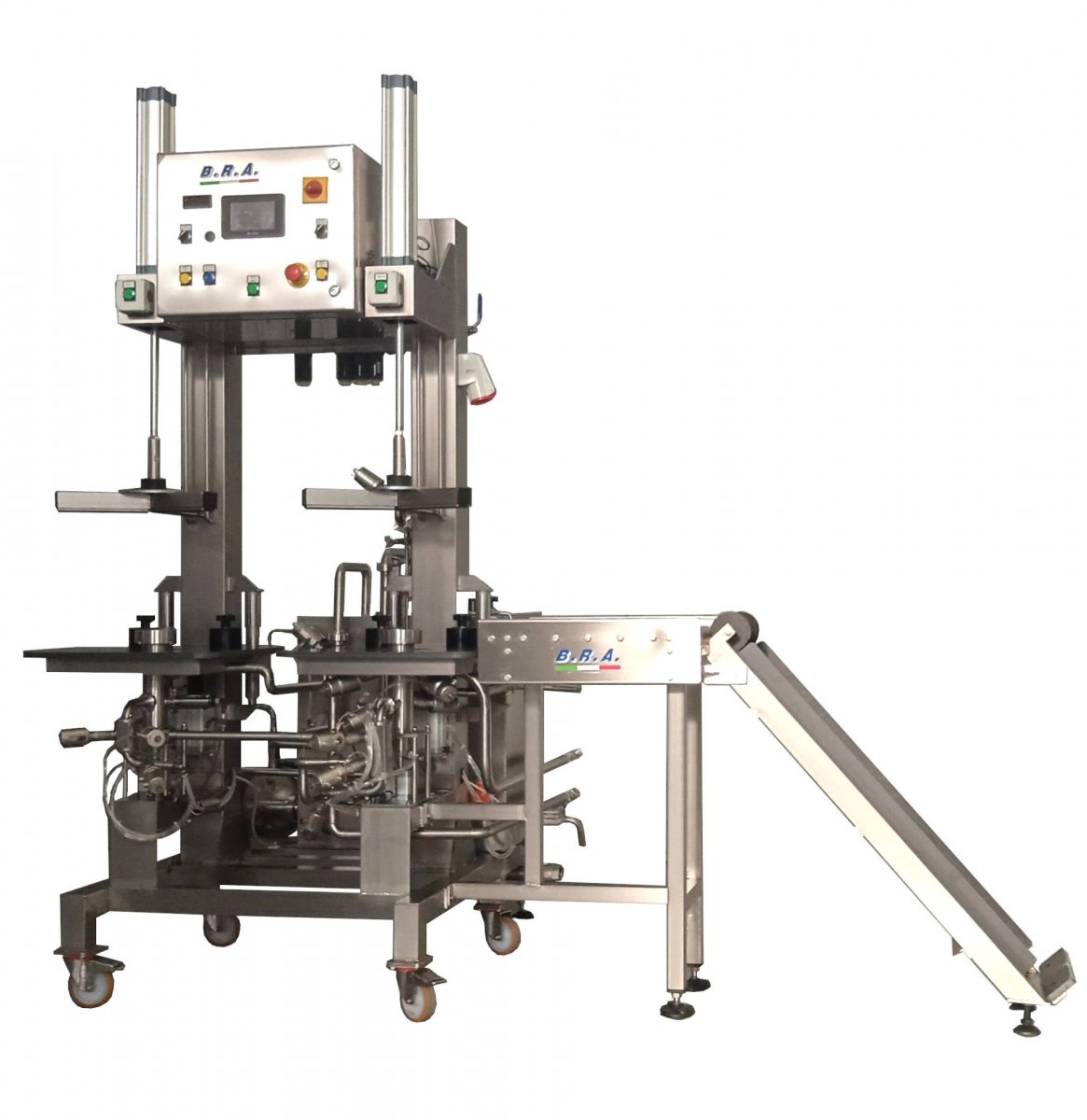

SEMI-AUTOMATIC FILLERS for 20÷50 l stainless steel kegs

Versions: ECO 1T model, with a single washing and filling head, ECO 2T model, with a head that washes the keg and a head that fills it

• Electro-welded A304 stainless steel frame and components in contact with the product compliant with food use

• Workable fittings, type and size of connections (product inlet, steam and drains) : any on request.

• Isobaric filling by steam sanitizable electromagnetic flowmeter for checking the filling cycle (in the cheaper version, level sensor for wine filling)

• Indicative hourly production: 20-23 stainless steel kegs/h of 25 l ECO 1T _ 36-40 stainless steel kegs/h of 25 l ECO 2T (Attention: the hourly production is indicative and may vary according to the machine settings).

• One or two rear tanks, depending on the product processed, for the detergent solutions.

• HMI PLC with touch panel that allows you to easily view and set the working parameters: it will be possible to save, edit and recall working recipes where is possible to store all parameters values. It is equipped with network connections that can be configured with the most common communication protocols (modbus, ethernet / IP, OPC UA) for interconnection to factory IT systems and / or automated integration with the logistics system or with other machines belonging to the production cycle (exchange of consents and / or data).

• Technology, present on all our lines, compliant with Industry 4.0

• It is possible to install a modem for remote assistance on the machine, if the buyer is at a great distance: this allows our technicians to provide remote support (at a distance) with direct interaction, sending commands and analyzing the relative responses from the software.

• Flow detection sensors on the washing / sterilization heads and keg temperature measurement sensor during sterilization

• Program supplied as standard to perform a washing / sanitizing cycle of the entire system (C.I.P.)

• The work cycles are completely automatic: the loading, unloading and handling of the kegs, usually by an operator, can be facilitated by integrating the machine with roller conveyors and / or slide.

• Voltage and frequency adaptable to the electrical standards in use in the Country of final destination.

Request info