Description

The internal cleaning of the internal keg is essential to eliminate any residue and / or harmful substance, preventing contamination of the product during the filling process.

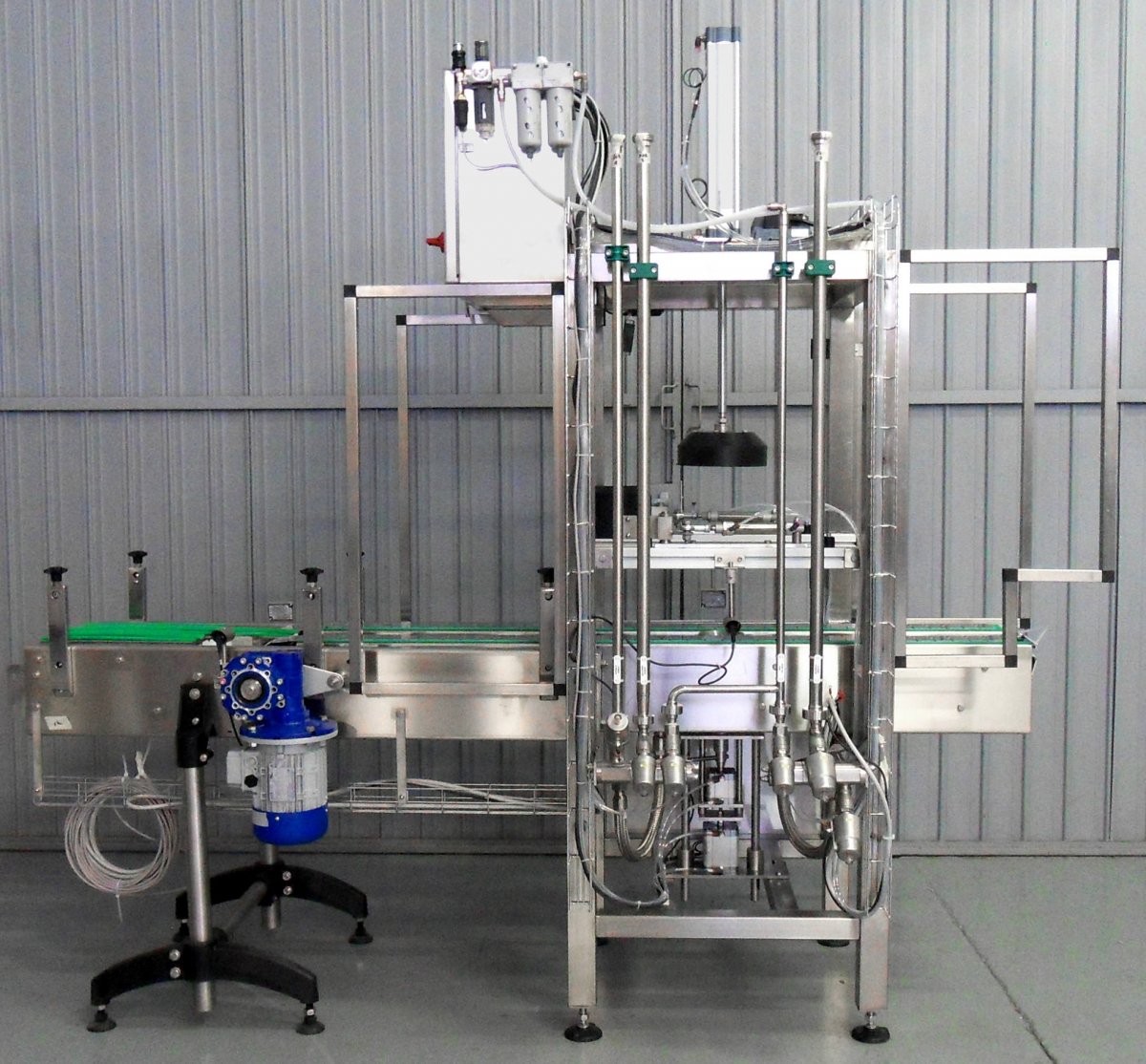

ECO 1T semi-automatic keg washer: this model is a stand-alone machine that works autonomously, with 1 washing head: equipped with two rear tanks of 110 l-175 l for acidic and basic solutions, it can have on request a third tank for the sanitizing solution.

The work cycles are completely automatic, except for the loading and unloading operations which are the responsibility of the operator.

- Tanks and entire structure in electro-welded A304 stainless steel

- in AISI 304 stainless steel

- Resistors for heating the basic detergent and pumps for fluid recirculation

- Flow detection sensor on the washing / sterilization head and keg temperature measurement sensor during sterilization

- PLC JAZZ with numeric keypad and two B / W command lines for the control of the machine and its work cycle. Allows you to easily view and set the working parameters; it will be possible to save, modify and recall the working recipes and memorize all the parameter values.

- Voltage and frequency adaptable to the electrical standards in use in the final destination Country.

RS model (soda filler) is a machine that works inserted in a washing and filling line, that enhance the internal washing phase of the kegs before their filling, with an independent control panel.

- Entire structure in electro-welded A304 stainless steel

- Pumps for fluid recirculation.

- PLC JAZZ with numeric keypad and two B / W command lines for the control of the machine and its work cycle. Allows you to easily view and set the working parameters; it will be possible to save, modify and recall the working recipes and memorize all the parameter values.

- Voltage and frequency adaptable to the electrical standards in use in the final destination Country

On both models it is possible to request the installation of the technology (ex. PLC HMI with touch panel) compatible with Industry 4.0

Request info