Description

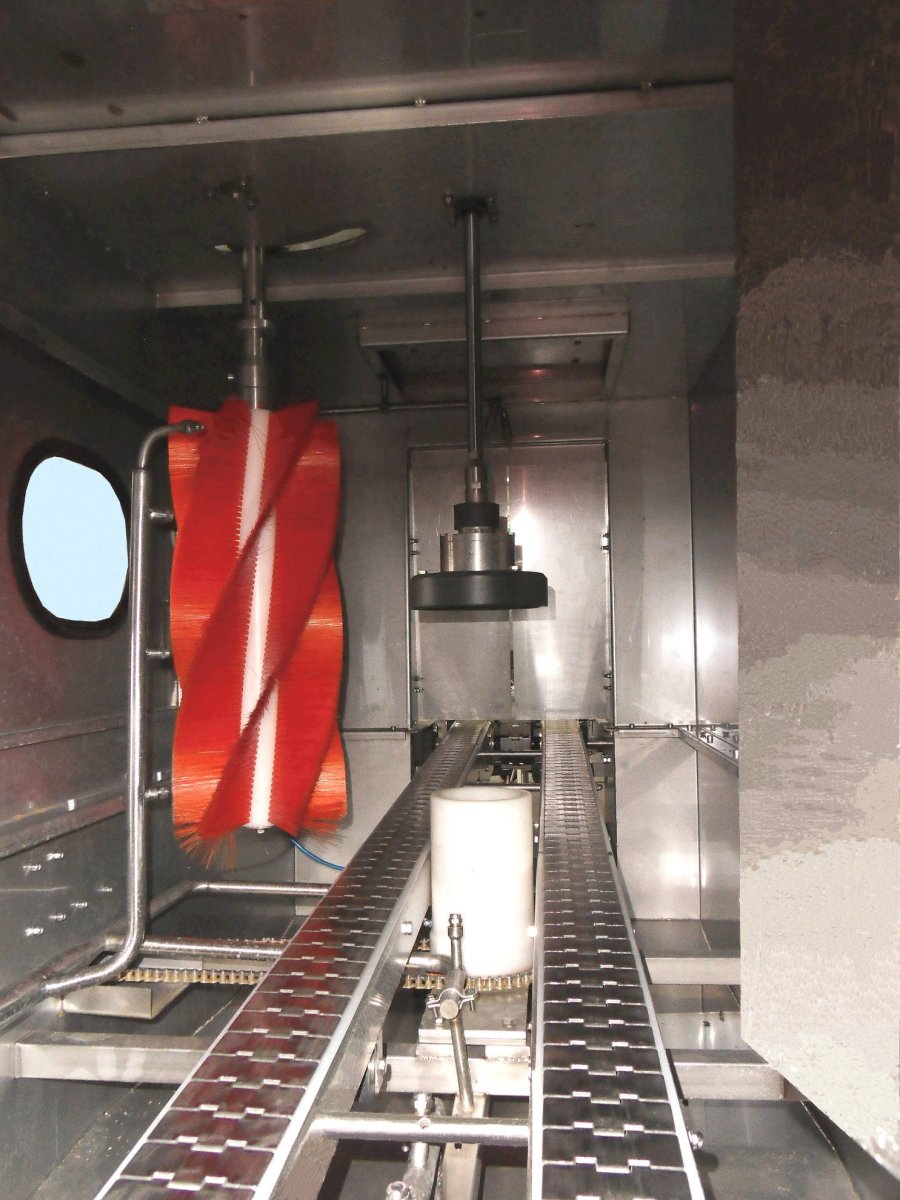

Designed for washing the external surface of steel kegs by a rotating brush and a nebulization system by nozzles for detergent solution and rinsing water.

• control panel AND Entire structure in electro-welded A304 stainless steel

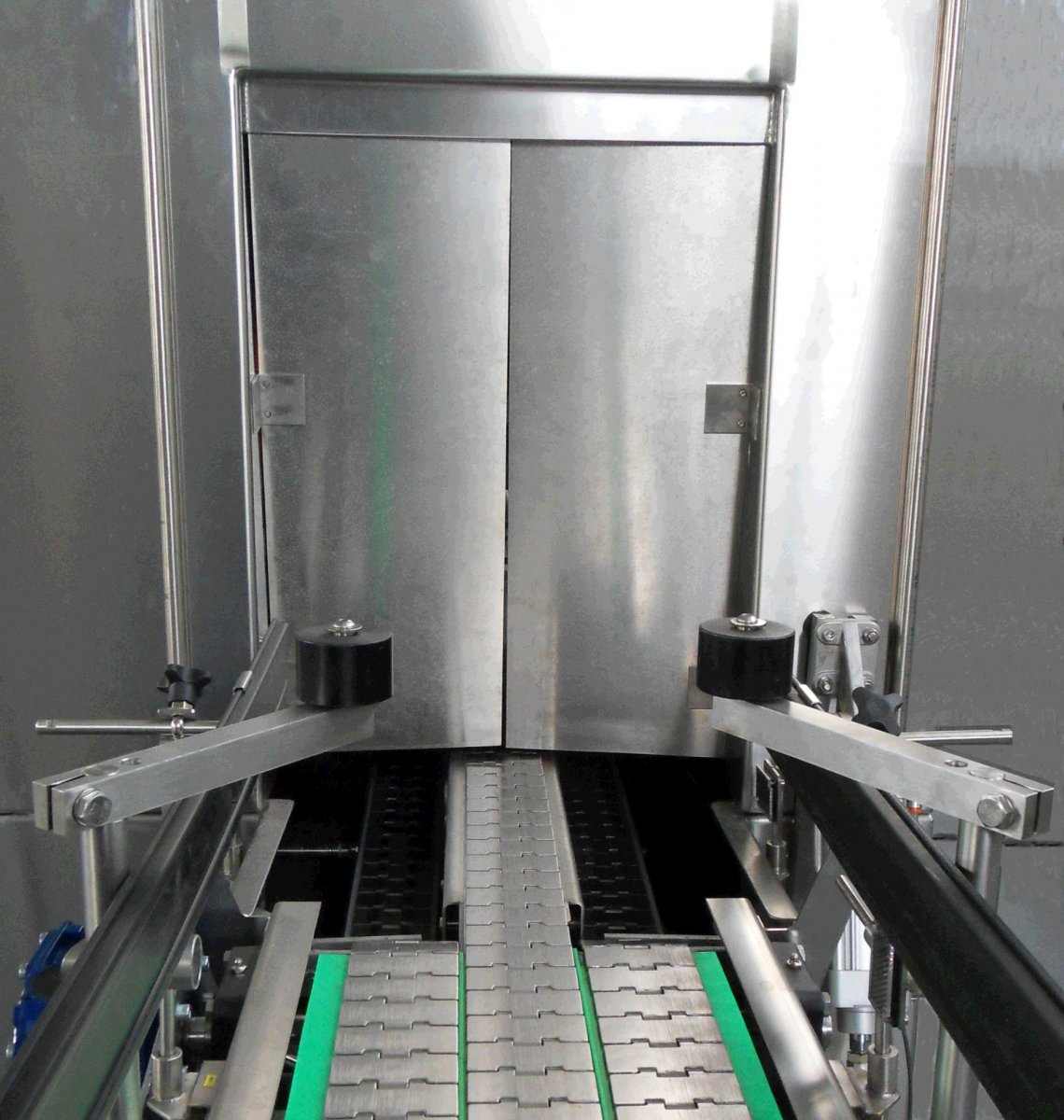

• Double-leaf doors at the entrance and exit and emovable front porthole

• A motorized conveyor for feeding the line, of agreed length, complete with motorization and automatisms for the separation of the incoming kegs

• Pump for fluids recirculation and water reserve tank

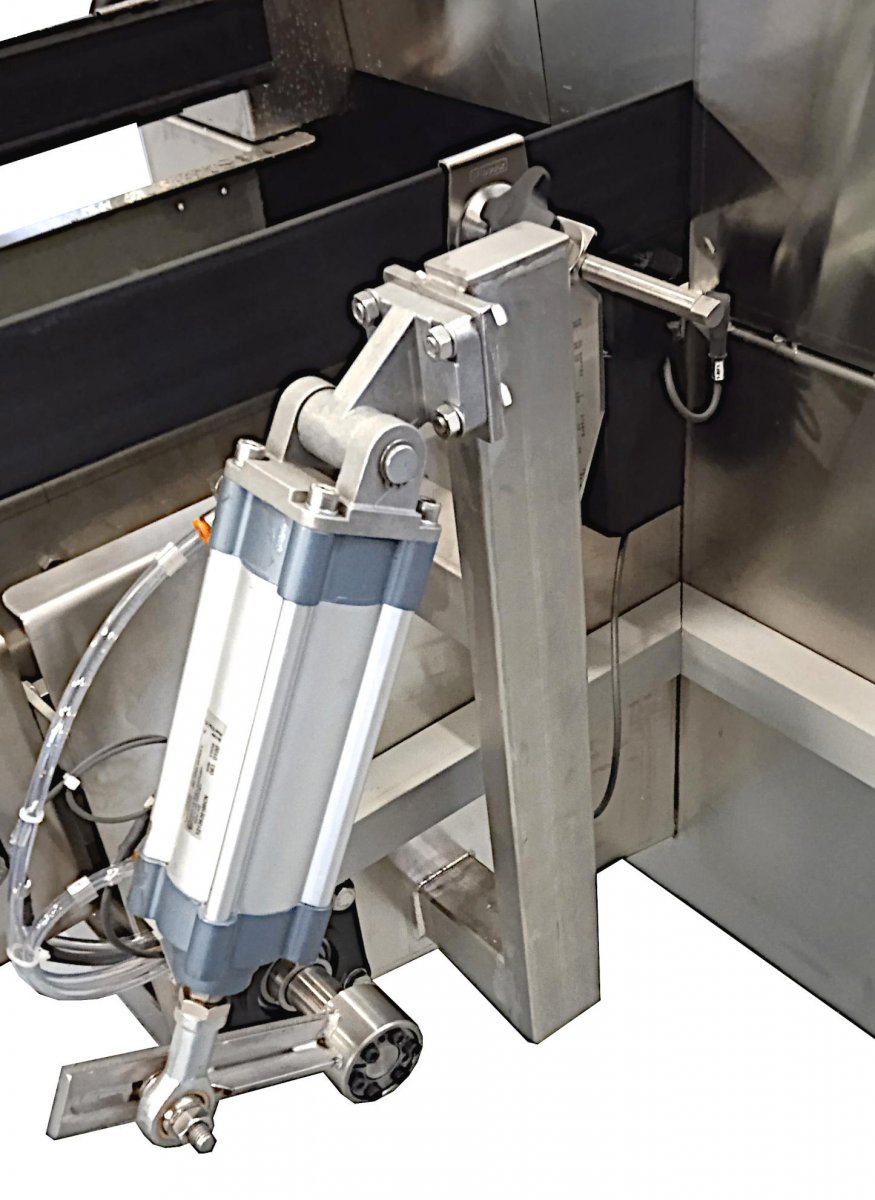

• Dosing pump and electro-pneumatic dosing system for detergent solution

• Motor with chain transmission for keg rotation

• Spiral cylindrical rotating brush: motor with chain transmission for brush rotation and pneumatic system for the lateral movement of the brush

• Keg drying system with air

• The HMI PLC with touch panel allows you to easily view and set the working parameters and compliant technology for Industry 4.0

• Work phases: Pre-wash with mains water - Washing by simultaneous opposite rotation of the keg and the brush - Release and drying of the keg

• Voltage and frequency adaptable to the electrical standards in use in the final destination Country

• Indicative hourly production: 60 kegs/h

• Possibility, through specific software, to exclude the washing cycle of the External Keg Washing Machine and to use only the transport systems (conveyor belts), if the washing machine is connected to a multifunction filler that also processes PET drums (which do not require washing)

CUSTOMIZABLE MODEL

Request info