Description

Our SIRIO 20 is a semi-automatic filler, suitable for a wide range of liquid and viscous pumpable products, food and non-food.

• Stainless steel frame on fixed feet or on wheels support surface of the bag adjustable in height and inclination

• 1 cap pick-up head (standard) and false neck for washing the machine

• Indicative hourly production: 180 bags /h 5 l Bag’s capacity: 3 / 5 / 10 / 20 l

• Workable caps: Vitop – Flex Tap – Press Tap – CMB – QCD (at request)

• UNITRONICS JAZZ T40 PLC and magnetic flow-meter in 316 stainless steel that can be vaporized.

• Pneumatic bag holder gripper with bag release at the end of the cycle.

• Program with 3-position selector: 1: step by step / 2: automatic / 3: washing

• Fully automatic filling cycle and vacuum packaging: once the liters to be dispensed are set on the PLC, as soon as the operator takes his hands away from the safety barriers, the machine starts filling.

• Automatic blowing with nitrogen at the end of each filling cycle that guarantee asepticity to the product and the cleaning of the valve neck.

• Predisposition for washing in recirculation.

• Product supply: 0,5 ÷ 1,5 bar Filling temperature: 0÷60° C

• Air supply: 8 bar dry and microfiltered

• Gas supply: 0,4 – 0,6 bar

• Product connection: on request

• Power supply: voltage and frequency adaptable to the electrical standards in use in the Country of final destination.

• Protective barrier in polycarbonate for the operator and for the pneumatic elements.

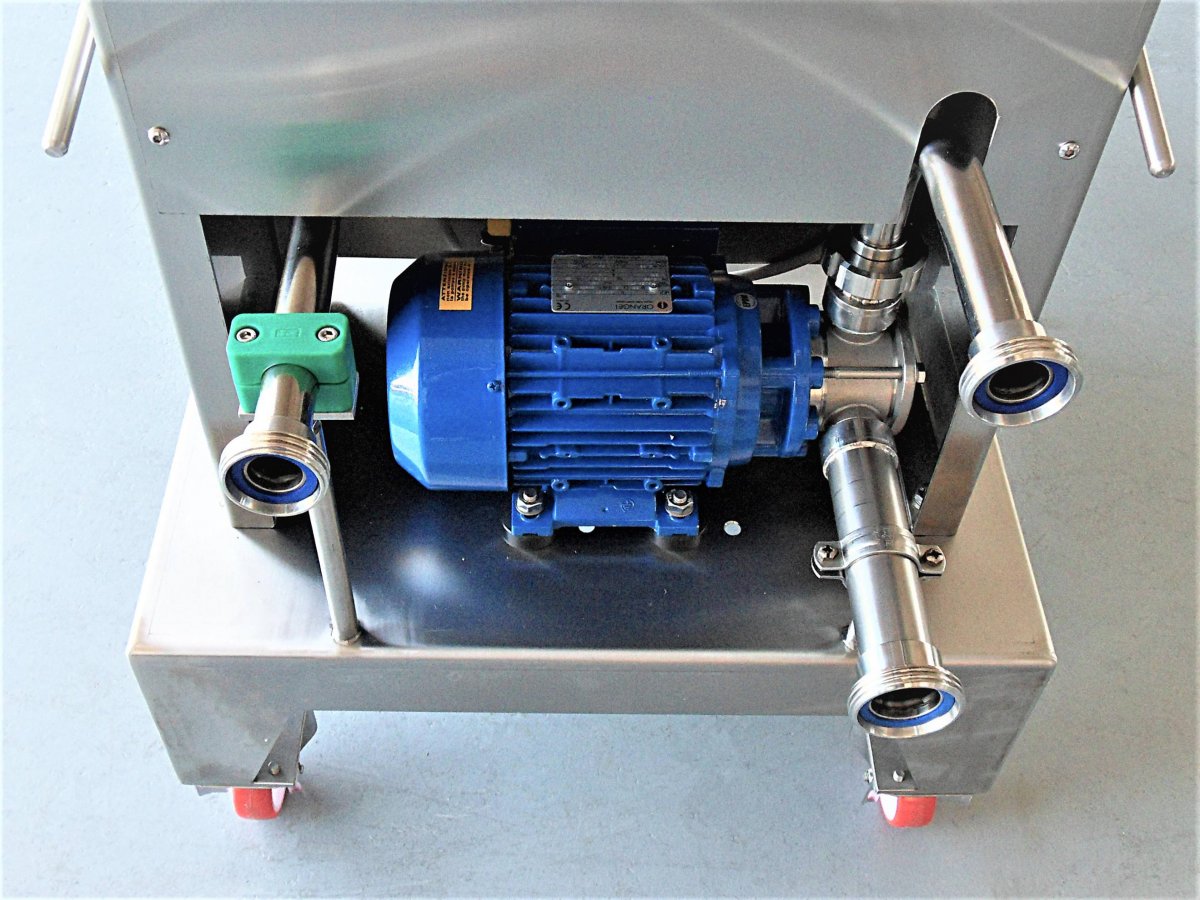

• On request it is possible to equip the machine with a support surface for the box, which facilitates the packaging and / or feeding pump phase.

Request info