Description

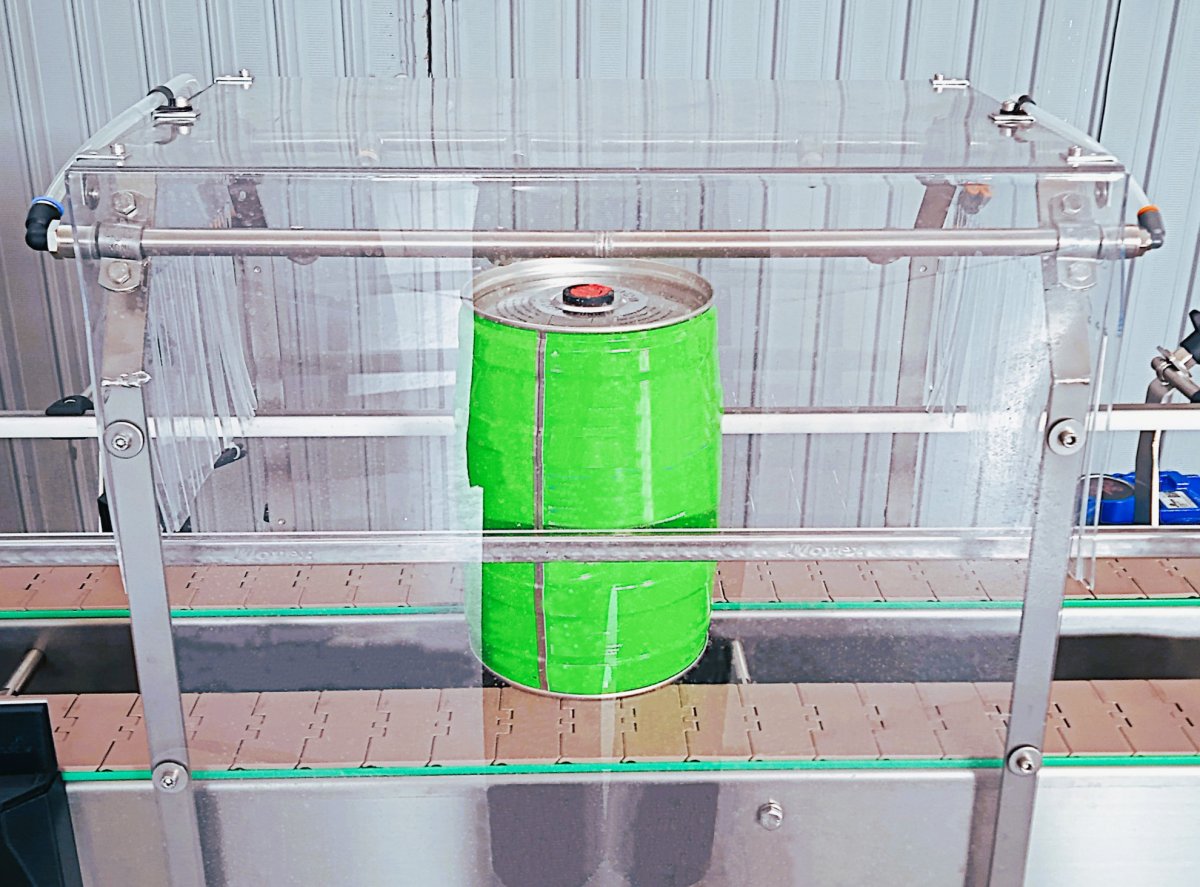

Automatic Filler: PARTY FILLER for stainless steel Party Kegs 3 or 5 L , whith 2 or more filling heads, complete with conveyor systems (belts and / or roller conveyors) at the inlet and outlet, customizable according to the available spaces.

* Electro-welded A304 stainless steel frame

* Supplied kit for the washing phase of the system and, on request, kit for format change (from 3 to 5 litres and vice versa)

* Isobaric filling by electromagnetic flow meter

* Keg Checking System via retro-reflex sensor: checks that the keg had no plugs or obstructions and is ready for filling

* Keg Stoppers via retro-reflex sensors: lthe keg locking levers are activated automatically and synchronized when the kegs arrive under the filling heads

* HMI PLC with touch panel that allows you to easily view and set the working parameters: it will be possible to save, edit and recall working recipes where is possible to store all parameters values.

* The HMI touch screen PLC is equipped with network connections that can be configured with the most common communication protocols (modbus, ethernet / IP, OPC UA) for interconnection to factory IT systems and / or automated integration with the logistics system or with other machines belonging to the production cycle (exchange of consents and / or data).

* Technology compliant with Industry 4.0.

* It is also possible to install a modem for remote assistance on the machine, if the buyer is at a great distance: this allows our technicians to provide remote support (at a distance) with direct interaction, sending commands and analyzing the relative responses from the software.

* Software programs: one filling cycle, two C.I.P. cyles and one P.T.F. cycle

The line can be enriched with other elements:

* Capping station: here the operator places the cap on the full keg, which is then sealed by pneumatic movement

* External keg rinsing station from product residues

* Keg drying station by blowing air

* Type and size of connections: any on request

* Manual loading and unloading of the kegs

* Voltage and frequency adaptable to the electrical standards in use in the final destination Country.

* Productivity: 200 kph (data may vary based on operator settings / recipes, product temperature and pressure and distance from the container it comes from)

Request info